Athlos is an X-ray imaging sensor developer and manufacturer, specializing in x-ray imaging based on CdTe and Si combined with proprietary full custom CMOS readout.

Ultra fast X-Ray Imaging (UFS)

- X-Ray Ultra-Fast Imaging (UFS)

- Single Photon Sensitive

- High Dynamic Range

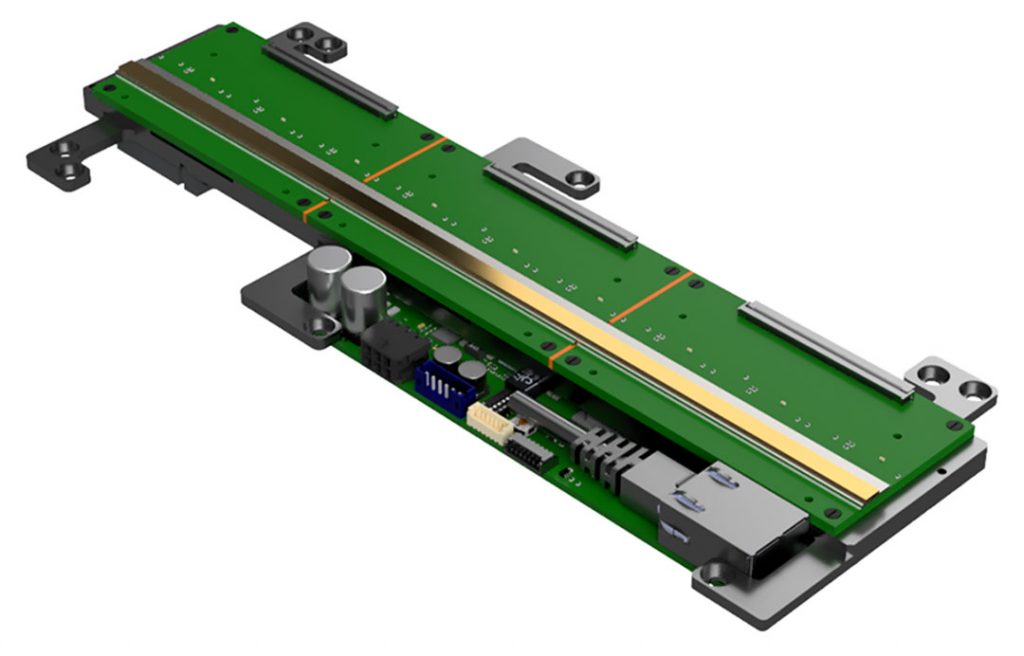

UFS, Ultra-Fast Scanner, represents a market benchmark performance in fast scanning x-ray imaging. Our scanners utilize the latest CdTe-CMOS direct conversion technology. UFS achieves scanning speeds of up to 300m/min @ 400µm resolution or 60m/min @ 100µm resolution. The maximum x-ray flux is 50*10**6 / (sec * mm 2 ) with single photon sensitivity and quantum limited performance down to 2 nGy doses. UFS offers various ways of integration to OEM systems including a variety of external triggering options for synchronization with mechanical and moving parts (e.g. belts), kinematic and speed profiles. For applications with need for dual energy (material differentiation) UFS can be synchronized to kV pulsing x-ray source(s) enabling high speed dual energy imaging or synchronizing to dual focal spot x-ray block.

Intraoral X-Ray Imaging

- True Wireless (Bluetooth®)

DC-Air ® is a Direct Conversion x-ray imaging intraoral sensor, truly wireless, operating with Bluetooth ®. It is comfortable and safe to the patient while its direct conversion technology increases diagnostic efficacy. Due to it being completely wireless it is versatile and improves the workflow in dental practices. It is the first intraoral sensor to offer film-like sharpness (direct conversion), phosphor plate-like comfort (wireless, unique design) and real time imaging.

Direct Conversion X-Ray Imaging

(CdTe-CMOS & SI-CMOS)

Direct conversion x-ray imaging with CdTe-CMOS or Si-CMOS is the technology enabling the direct conversion of x-ray photons into electric pulses collected on the pixels of full custom CMOS readout substrates and thereby substantially improving image sharpness, contrast resolution, sensitivity and dynamic range.